Advancing water electrolysis technology for the production of green hydrogen energy

In the latest occasions, hydrogen has drawn major focus as a potential thoroughly clean electricity source as an alternative to fossil fuels. In individual, there has been lively investigation and advancement of water electrolysis technologies that extracts hydrogen from water to generate eco-friendly power and avoids the emission of greenhouse gasses. The proton exchange membrane water electrolyzer (PEMWE) technologies, which is at present existing in some handful of highly developed international locations holds core product engineering and employs high-priced noble steel-dependent catalysts and perfluorocarbon-centered proton exchange membranes. Such technology success in higher expenses of procedure manufacturing. To deal with these constraints of the typical know-how, a study team in Korea has not too long ago produced core technological innovation for the following-technology water electrolysis technique that has noticeably enhanced the toughness and efficiency whilst noticeably reducing the value of producing eco-friendly hydrogen energy.

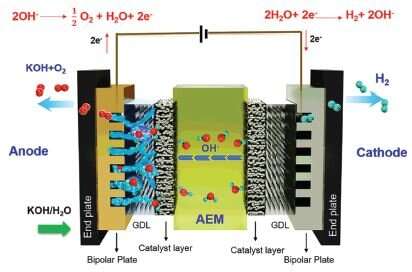

Korea Institute of Science and Technology (KIST, President Yoon, Seok-Jin) announced the project underneath the joint exploration concerning the investigate group of Dr. So Youthful Lee at the Center for Hydrogen and Fuel Mobile Study and beneath Prof. Youthful Moo Lee of the Division of Strength Engineering, Hanyang College, a membrane electrode assembly (MEA) for anion trade membrane water electrolyzers (AEMWE) was formulated that is predicted to substitute the costly current PEMWE technology.

AEMWE, which works by using an anion exchange membrane and electrode binder, does not rely on the expensive platinum team-steel electrodes and replaces the separator plate substance of the drinking water electrolysis mobile with iron as a substitute of titanium. When comparing the rate of catalyst and separator content by yourself, the production charge is diminished by somewhere around 3,000 times that of the existing PEMWE. Having said that, it has not been commercially used owing to its minimal overall performance in comparison to that of the PEMWEs and sturdiness troubles of less than 100 h of sustained operation.

The exploration workforce designed poly(fluorenyl-co-aryl piperidinium) (PFAP)-centered anion trade elements (electrolyte membrane and electrode binder) with high ion conductivity and sturdiness under alkaline conditions by growing the particular floor region within the structure and primarily based on this know-how, a membrane electrode assembly was designed. The created materials represented superb toughness of much more than 1,000 h of operation and has attained a new report mobile efficiency of 7.68 A/cm2. This is about 6 periods the efficiency of present anion trade resources and about 1.2 moments that of the costly business PEMWE technological know-how (6 A/cm2).

The engineering has triumph over the effectiveness and longevity difficulties of the core supplies pointed out as limitations in the AEMWE technology to day and has elevated the top quality of the engineering to such a degree that makes it possible for substitute of the PEMWE technology. In addition to the excellent functionality and toughness, the commercialization of the created anion exchange membrane components has been underway with the incorporation of substantial-capacity and significant-space applications.

Dr. So Youthful Lee of KIST explained that their “crew has developed a content and higher-efficiency technological innovation that goes further than the constraints of the existing drinking water electrolysis technologies. This technologies is predicted to lay the foundation for introducing the subsequent-technology drinking water electrolysis engineering that makes it possible for a important reduction of the price tag concerned in the green hydrogen creation.” Professor Youthful Moo Lee of Hanyang University stated that “the created substance has a high possible for application as a main materials for not only h2o electrolysis but also for the hydrogen gasoline cells, carbon seize utilization and direct ammonia gas cells, which are the following-era hydrogen business.”

The research was revealed in Energy & Environmental Science.

Nanjun Chen et al, Significant-efficiency anion exchange membrane water electrolyzers with a latest density of 7.68 A cm−2 and a sturdiness of 1000 hours, Strength & Environmental Science (2021). DOI: 10.1039/D1EE02642A

Offered by

Nationwide Research Council of Science & Technological innovation

Quotation:

Advancing h2o electrolysis engineering for the creation of eco-friendly hydrogen energy (2022, January 28)

retrieved 29 January 2022

from https://techxplore.com/information/2022-01-advancing-electrolysis-know-how-production-green.html

This document is topic to copyright. Aside from any good dealing for the purpose of non-public study or investigate, no

part could be reproduced without the composed permission. The written content is offered for info applications only.