Lifting arm concept and automated repair training to propel portable repair system

GFM’s Moveable Scarfing/Composite Maintenance Procedure (PS/CRS) concept aims to allow transportable, digitized inspection, scarfing and fix of huge composite constructions these types of as plane wings. New partnerships goal to present consumers a complete range of coaching, transportation and inspection possibilities. Photograph Credit score: AGFM

American GFM (AGFM, Chesapeake, Va., U.S.), the U.S. department of Austrian equipment instrument and composites producing devices supplier GFM, has been producing automated and portable restore know-how for composite aircraft and other elements considering that 2006. The newest iteration, termed the Moveable Scarfing/Composite Restore Process (PS/CRS), will be driven by software program from Wichita State University’s (WSU) Nationwide Institute for Aviation Study (NIAR, Kan., U.S.) to generate a digital thread of repair service information for a aspect and to use 3D scan details to inform the fabrication of a repair patch (for history and more on PS/CRS know-how, see “Moving toward portable, digitized composite part repair”).

According to Frank Elliott, highly developed initiatives coordinator at AGFM, the upcoming step will be to move the PS/CRS from the prototype stage to buyer use. In response to discussions with probable prospects, AGFM has lately fashioned several partnerships to supply expert coaching on the PS/CRS process, and devices for lifting the method on to an aircraft surface area and supporting its excess weight throughout scarfing and repair service.

Specialised composites mend instruction

Abaris Training Assets features courses in traditional subject restore procedures for composite parts as effectively as a new course for instruction on AGFM’s automatic program. Photograph Credit history: Abaris Schooling Resources

To support guarantee companies are geared up to run the PS/CRS technique, AGFM has partnered with Abaris Coaching Assets (Reno, Nev., U.S.) to offer you coaching on composite maintenance processes. This training will involve normal instruction on the basics of composite repair — scarfing, repair service patches, handbook field repair service strategies, strategies and repair via sizzling bonders, warmth blankets or other heat resources — in addition to a new program supplied covering AGFM’s automatic procedures.

Customized elevate arm strategy

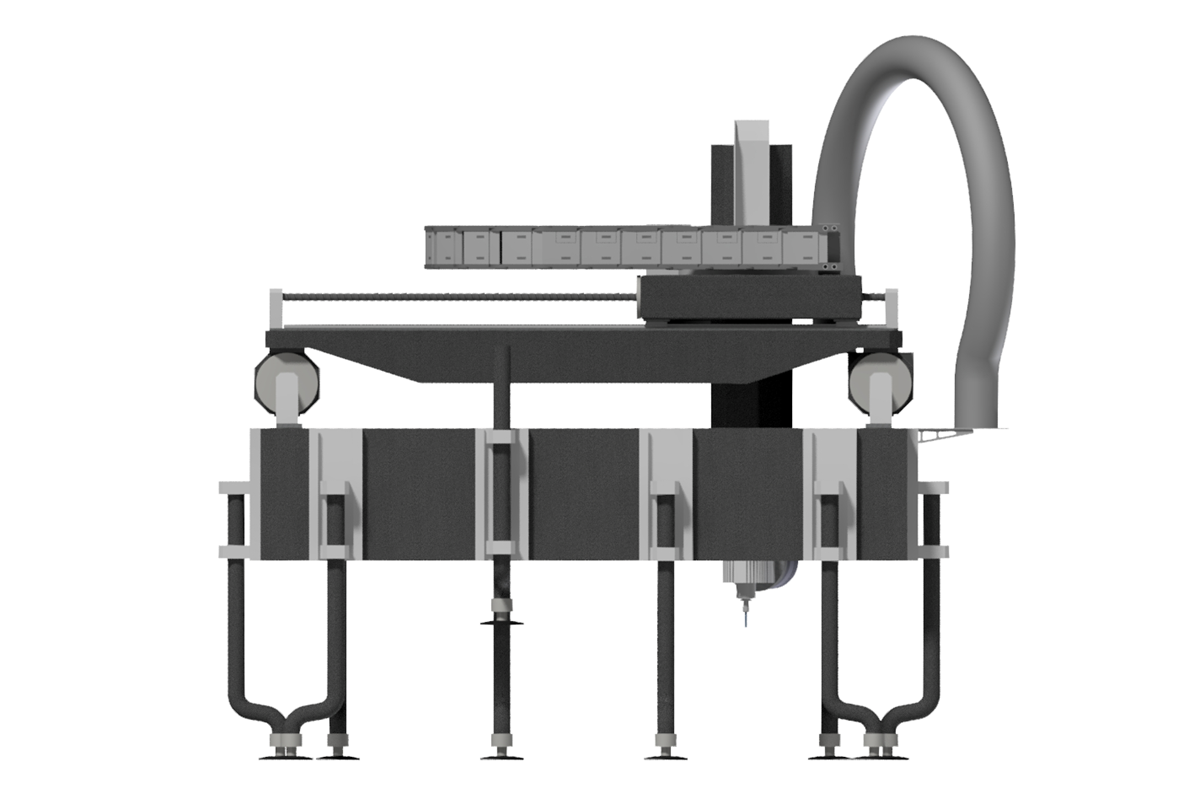

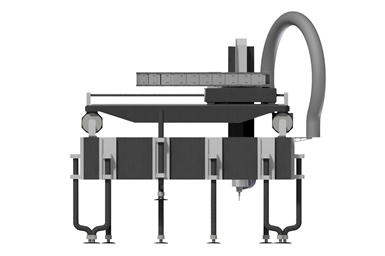

The PS/CRS contains a 5.4-foot x 5.4-foot x 4.75-foot frame that incorporates vacuum pods, a milling system with connected spindle device, an electronic and CNC box, a vacuum dust extraction procedure and an optional non-harmful inspection (NDI) and/or scanning system. The all round system is meant to be moveable — transportable to a subject internet site for on-website scarfing and inspection, even on the wing of an aircraft itself.

This principle lifting arm method is created to elevate and aid the PS/CRS instantly onto an aircraft or other composition. Image Credit history: Discipline Worldwide Group

To make this attainable, AGFM has partnered with world wide floor guidance equipment (GSE) provider Subject Intercontinental Team (Poole, U.K.) to develop a specialised lifting arm method for transporting the PS/CRS on to an plane or other construction. The elevate process will elevate the 320-pound PS/CRS frame to its appropriate area on an plane or other structure, and connect it to the portion area with vacuum pods.

The road-transportable principle involves a about 11-foot x 6-foot x 8-foot technique consisting of a system for holding the PS/CRS and a double increase with telescopic mast for lifting the PS/CRS on major of an plane wing or fuselage, or to lift and aid the PS/CRS upside-down underneath the wing for the duration of a repair.

Laser-primarily based inspection and automatic 3D scanning

In addition, AGFM has partnered with two suppliers to greatly enhance its scarfing procedure with inspection and 3D scanning abilities.

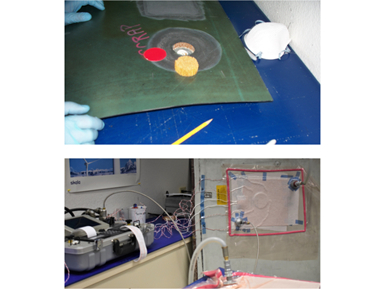

Aligned Vision (Chelmsford, Mass., U.S.) will supply its LASERVISION laser-based program, which is capable of automatic, in-situ inspection, verification and documentation of fiber orientation, foreign object debris (FOD) and substance site, as well as projected layup steering for composite maintenance. Elliott notes that the facts gathered by this method will feed into NIAR’s digital thread software.

LASERVISION can be run as a standalone procedure or integrated with the fix mobile personal computer by using PLC interface or by software progress kit (SDK) integration.

Aligned Vision’s LASERVISION (pictured still left) operates with the PS/CRS for laser-primarily based inspection and restore patch alignment. Zeiss’ T-Scan Hawk (correct) delivers 3D scanning for inspection or repair patch enhancement. Photograph Credit: Aligned Eyesight, Zeiss

In addition, Carl Zeiss Industrial Metrology LLC (Wixom, Mich., U.S.) will offer its T-Scan Hawk industrial 3D scanner to digitize the destroyed area region. The handheld guide laser scanner will be used by the operator on the get the job done platform even though the PS/CRS is becoming lifted and moved into location and connected to hte plane for repair. The T-Scan Hawk is said to allow quickly, objective measurement on hard portion surfaces for possibly inspection or enhancement of tooling or a mend patch. Elliott notes that AGFM has utilised Aligned Vision and Zeiss products successfully in its earlier restore assignments.

For much more details, call Frank Elliott at [email protected] or Jeswin Joseph, program and exploration supervisor at NIAR/WSU, at [email protected].